Carts & Dollies

Custom Carts & Dollies

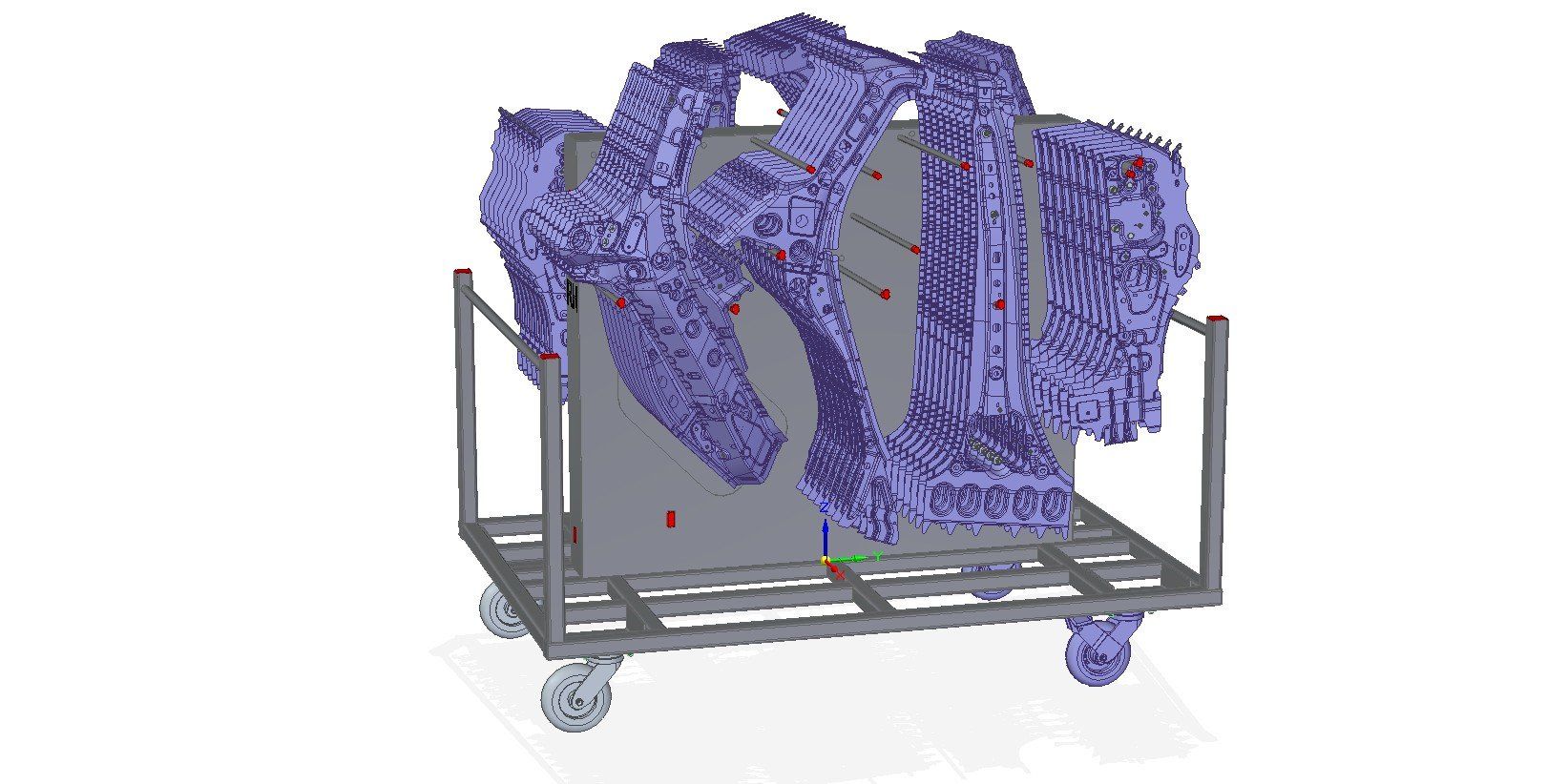

Utilizing our knowledge gained from years of designing returnable shipping racks and in-plant WIP racks, we also design a wide variety of carts and dollies. An existing automated or manual system can be incorporated into the designs, or each item can be designed to work independently. Simple or complex Ranly Design can create the cart or dolly to match any of your needs. Our dollies and carts are custom designed to meet your exact specification and material handling requirements. Custom dollies and WIP carts increase efficiency in manufacturing and warehousing facilities. This allows for better product flow, ease of mobility and increased productivity. It also increases safety and reduces material handling requiring the use of fork lifts or powered equipment. Reducing the loss time waiting for on product changeover lineside.

AGV Integration

Many companies have started to automate their systems and a large part of this automation includes using AGVs (Automated guided Vehicles) to move products throughout the plant. Use of AGV will dramatically reduce the forklift traffic and improve associate's safety. It also dramatically improves timeliness of lineside delivery of product and swapping out of empty containers. Whether your goal is reduced labor costs, higher order throughput, increased accuracy, greater productivity, or all the above. Our carts can be designed for and built with the AGV integration.

These carts can be designed to hold existing racks if you already have shipping containers for them. They can also be custom built to maximize part density for both the rack and the AGV capacity. No matter the product Rany Design can create an end product that increases your throughput and productivity to the next level. Our AGV carts offer, economical, safe distribution, and allows production operations to scale up throughput.

Paint Dollies and Hangers

Every dolly or cart completed by Ranly Design is customized to fit each customer's system and process. Regardless of the type of automated paint line you are running we can find your best solutions. We have years of experience in many different areas of the painting, powder coat, and E-coat systems. Custom designed and built hooks, paint line fixtures, hangers, and racks for automated conveyor systems. Each design takes into account optimum part density, loading ergonomics and quickest line changeover to keep your products moving through.

Proper parts racking has major impact on the operating efficiency, the correct application of the coating and the overall costs of the product. We can help you accelerate in all areas of production and profitability of the operation.

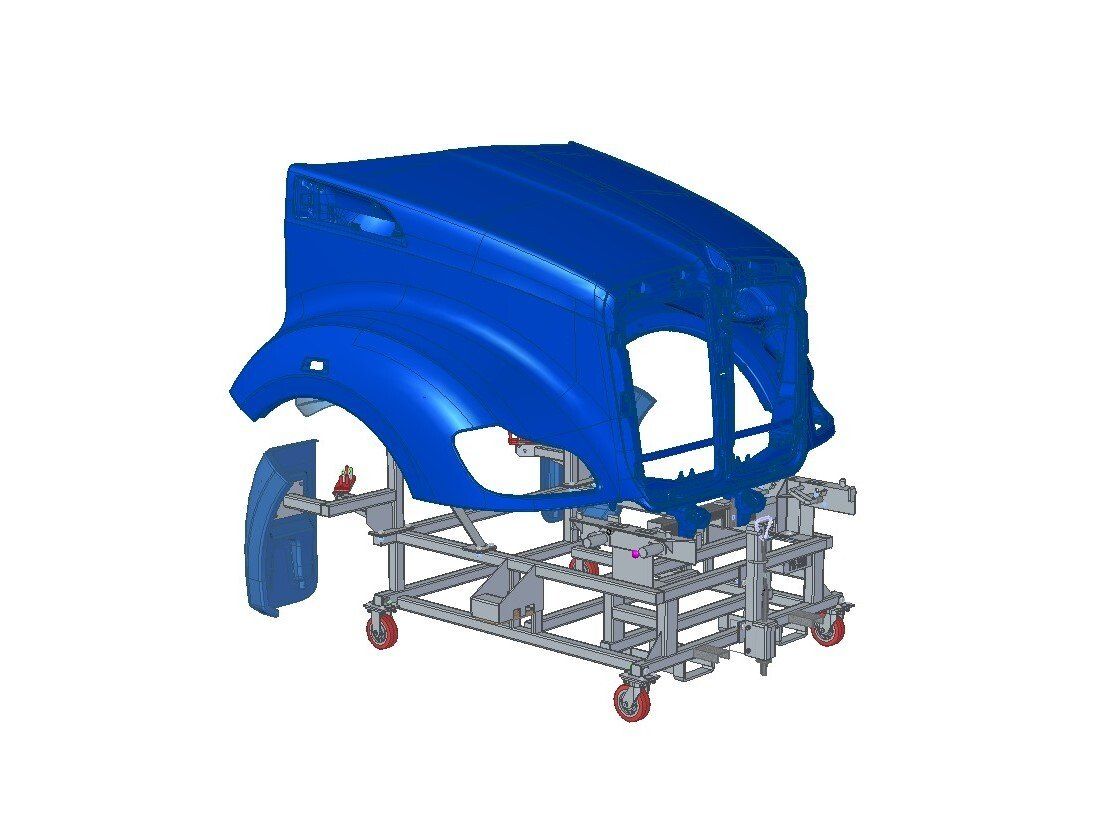

CAD Model Loaded with Hood and accessories

ButtonCab Companion Cart Prototype

ButtonCab Companion Cart Model

ButtonBrake Drum Cart Topper

ButtonBrake Drum Cart Topper Model

ButtonPneumatic Caliper Cart Topper

ButtonPneumatic Caliper Cart Model

ButtonSide Extender Carts

ButtonSide Extender Cart Model

ButtonHydraulic Caliper Cart Topper

ButtonHydraulic Caliper Cart Model

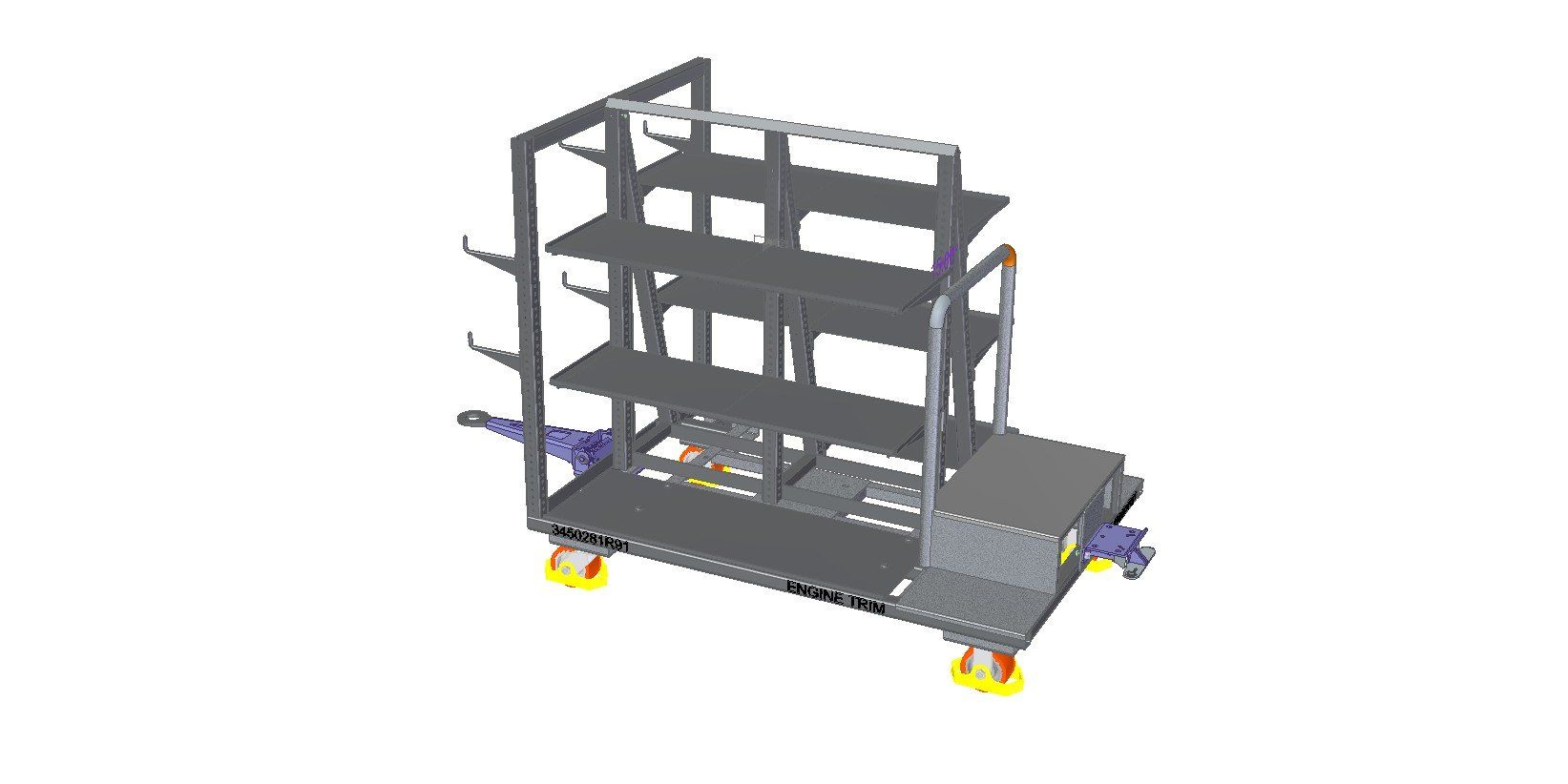

ButtonEngine Trim Cart Prototype

ButtonEngine Trim Cart Frame Painted

ButtonWorking Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

All Rights Reserved | Ranly Design

Site By: Midnet Media