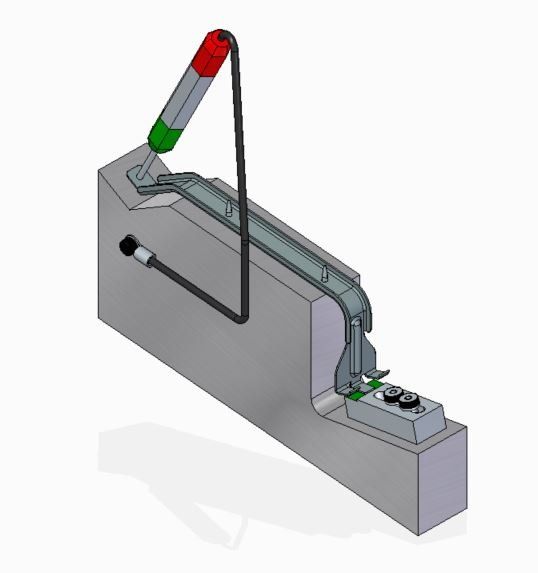

TOOL & DIE

Supported by decades of Tool Design engineering and Part Development experience.

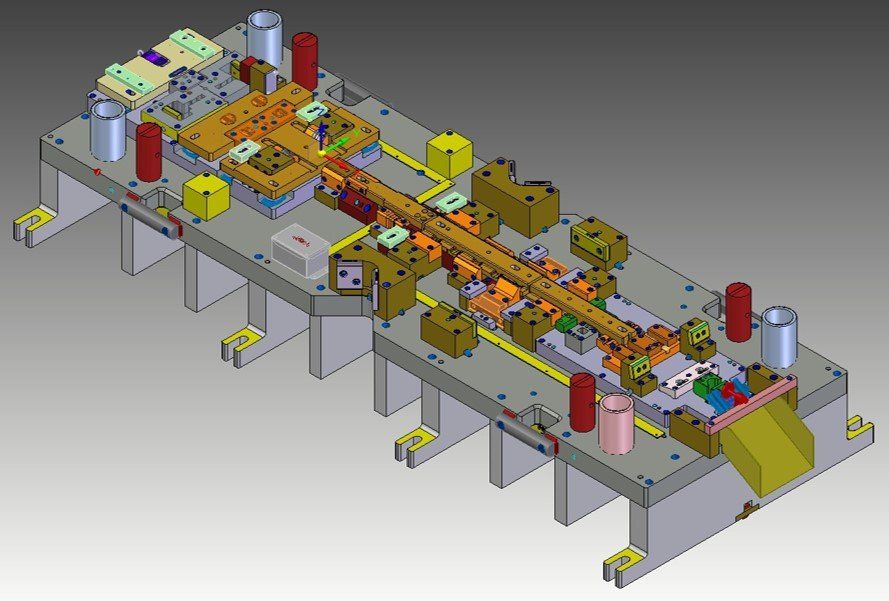

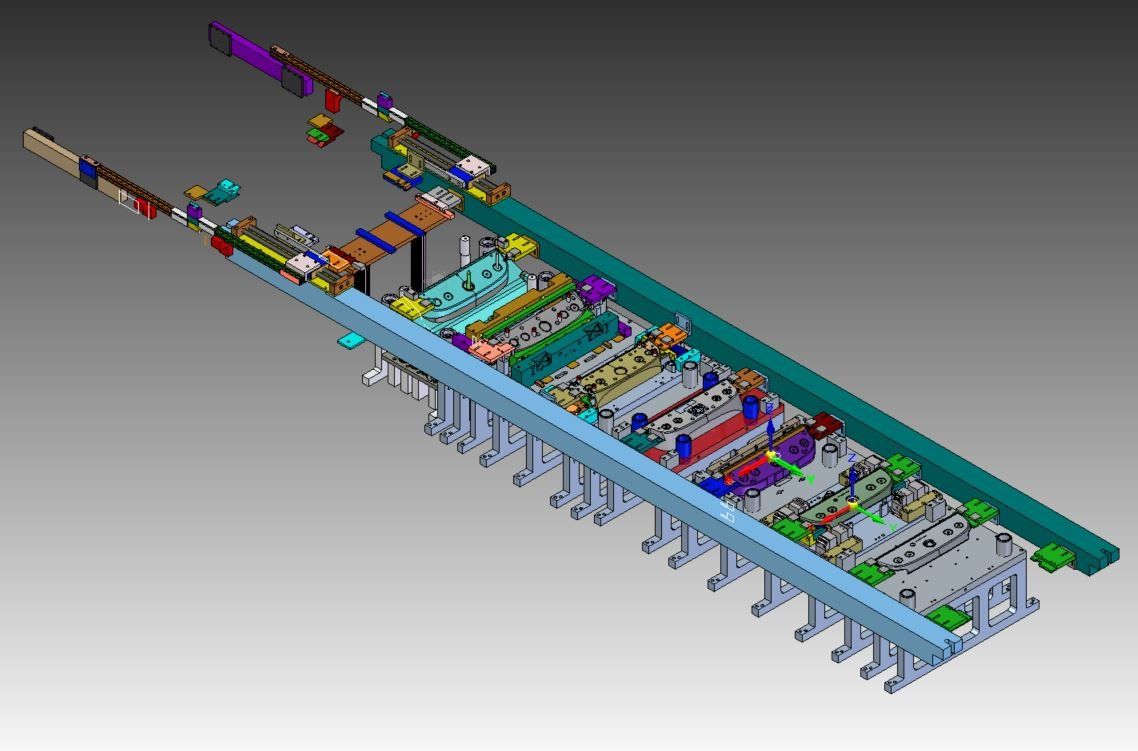

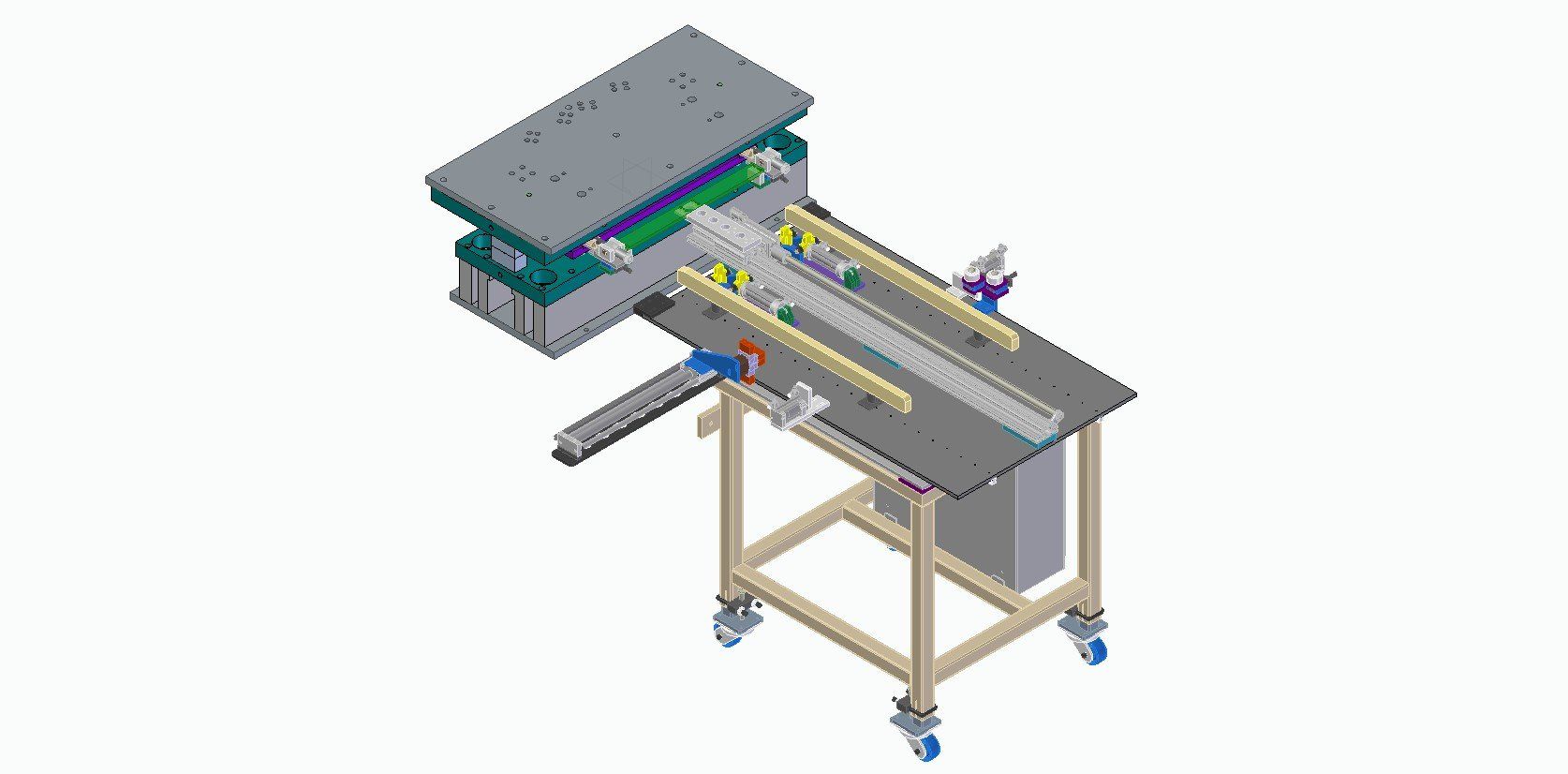

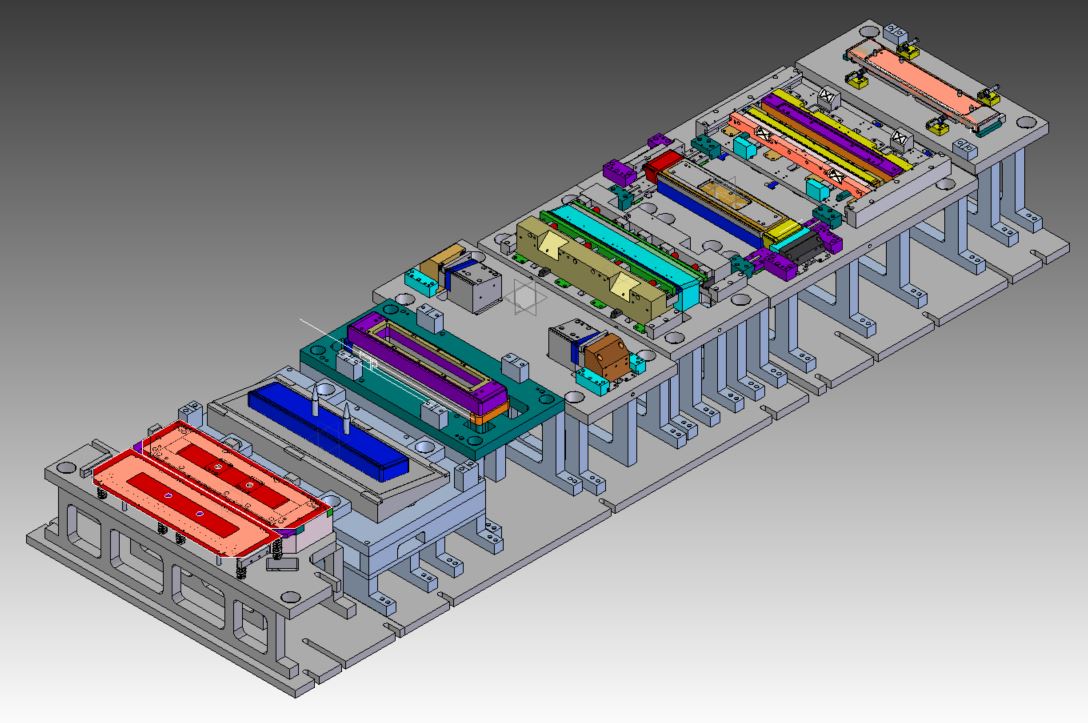

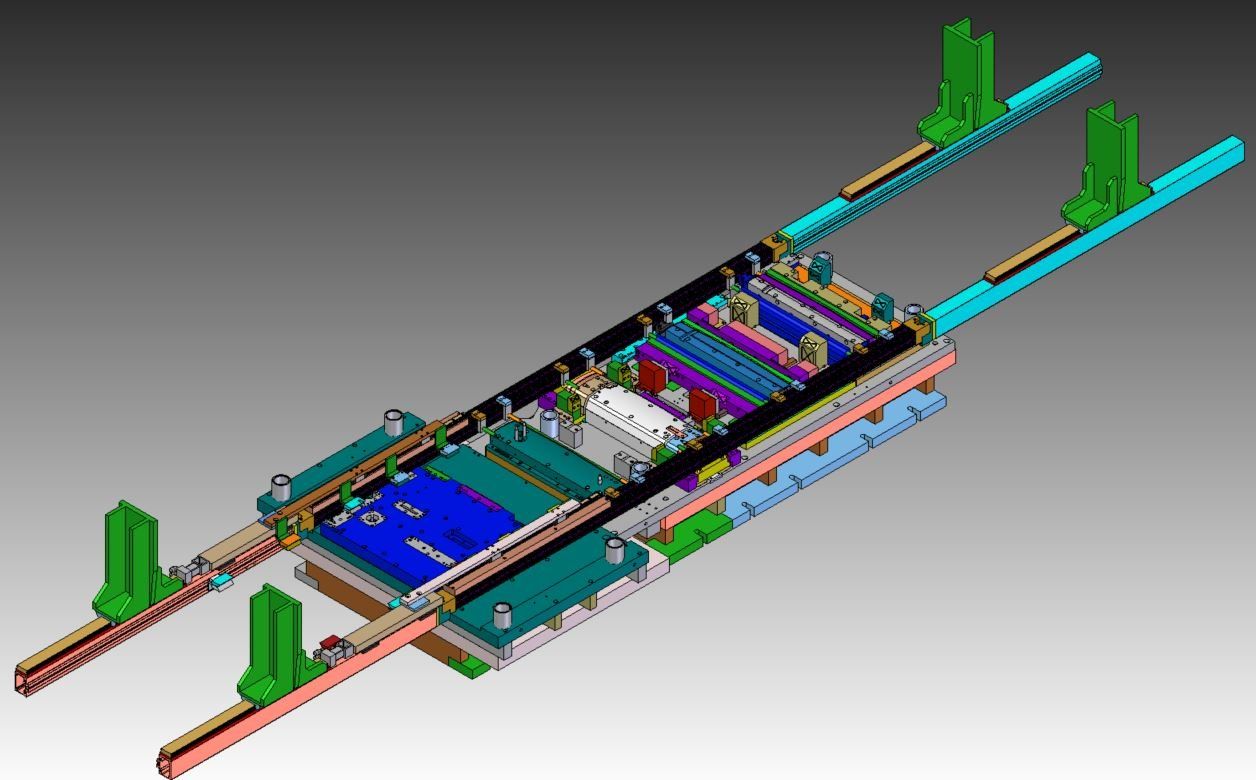

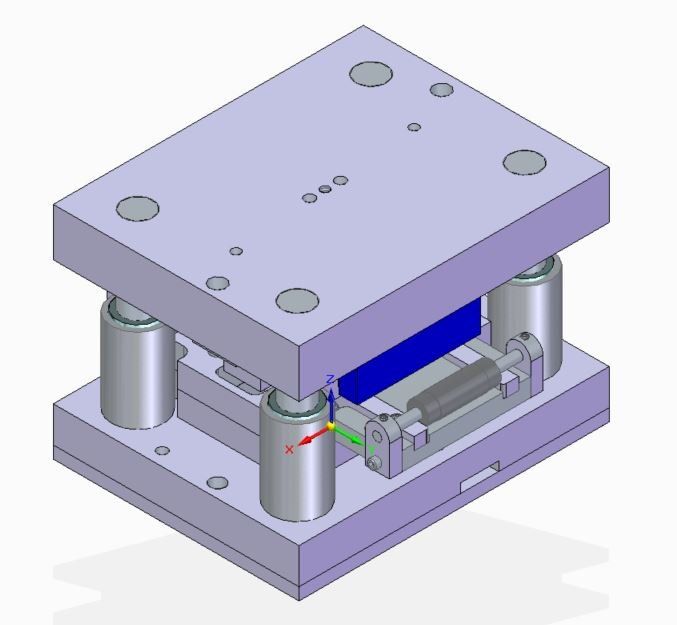

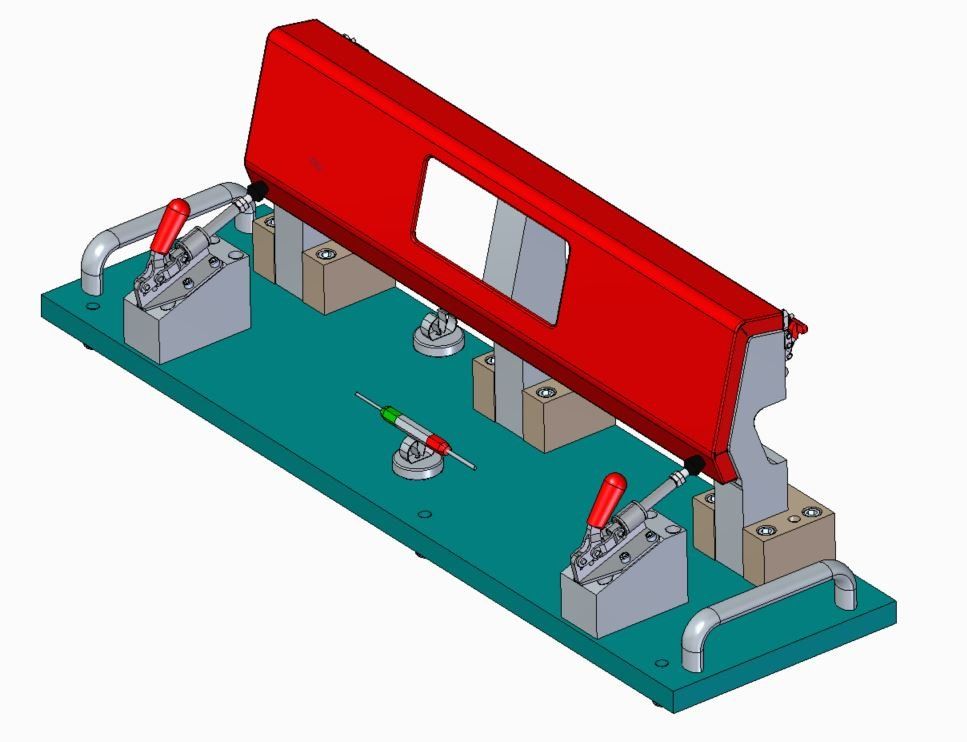

Knowing how dies fail in production, we draw from a wealth of experience to create greater production efficiency through a combination of proven tool design techniques that work and the art of a balanced and well thought out forming sequence. We design tools that can be manufactured at a reasonable price and will provide you with longer tool life.

We offer the choice to order tools from your toolmaker or Ranly Design can recommend a qualified supplier. Various options for part development assistance are also available on all jobs.

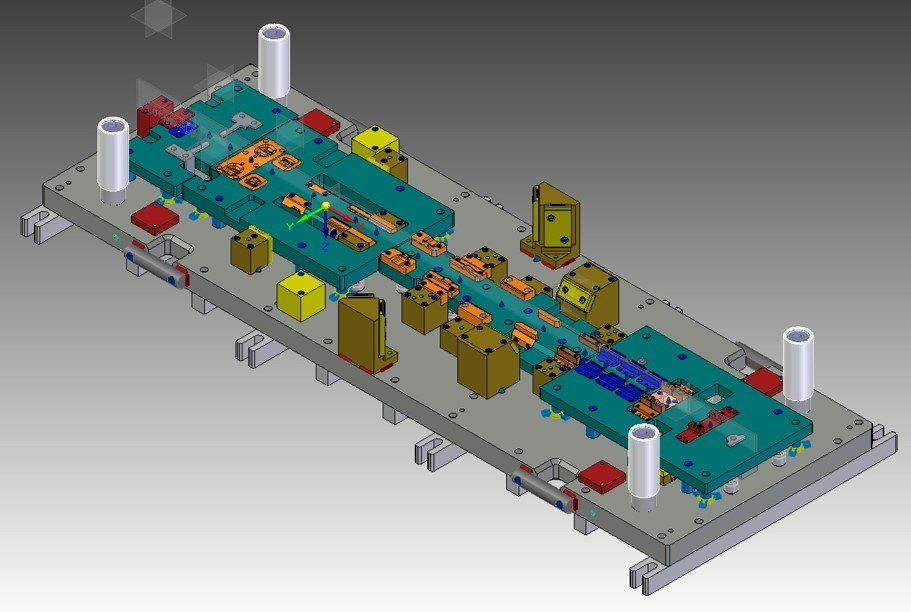

What Customers Receive

In purchasing a typical tool design package from Ranly Design a customer will receive:

- Part progression drawing showing preliminary dimensions for each station

- Individual forming station layouts showing operator setup dimensions

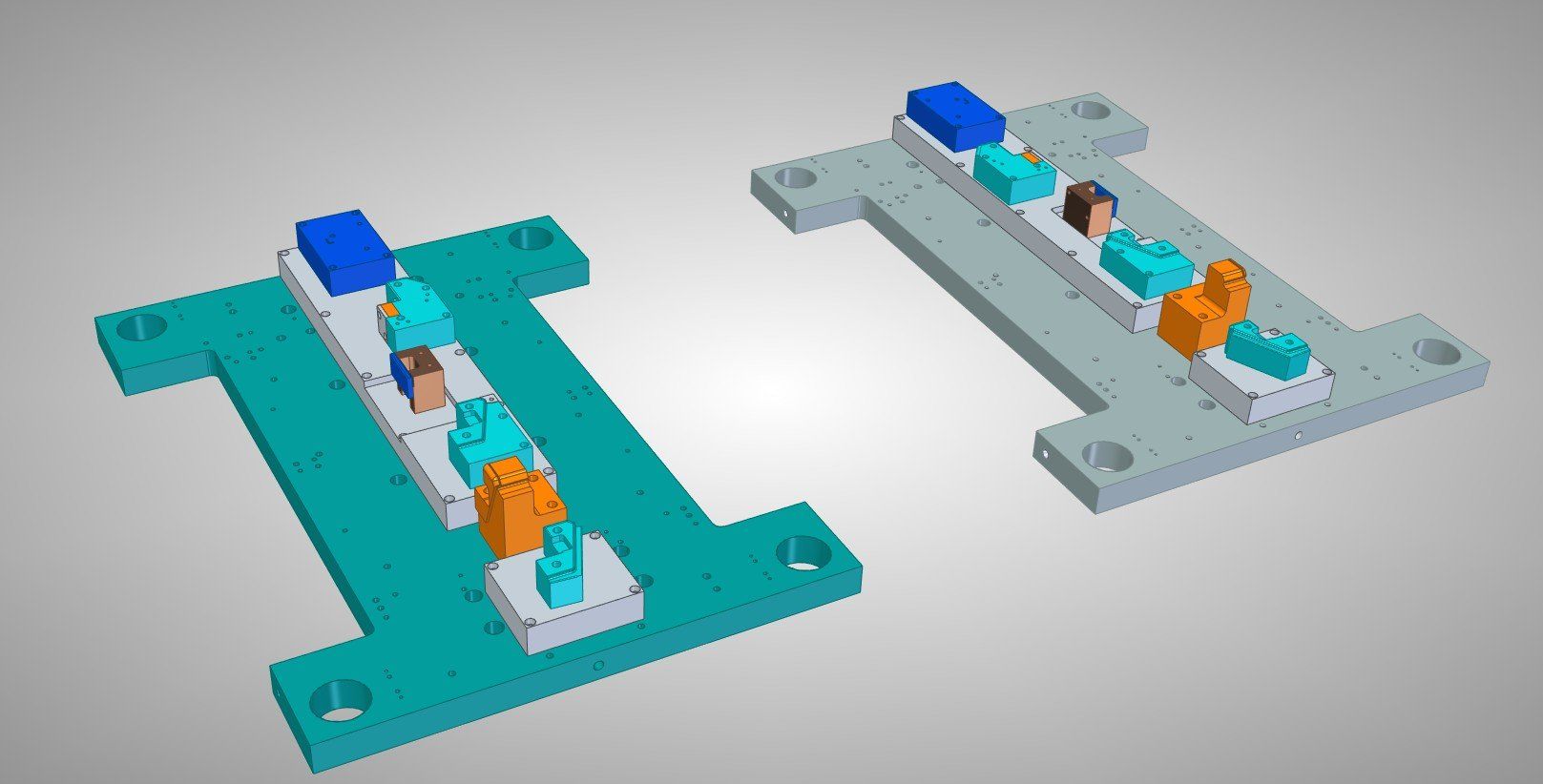

- 3D models & drawings produced using the most current version of Siemens Solid Edge solid modeling software

- Individual tool drawings

- Tool numbering system provided if none furnished by the customer

- Update of any tool drawings changed at end of part development

- Ongoing drawing changes are available at an additional charge

- Ranly Design drawing files will be provided upon completion in any of the following formats: AutoCAD DWG, PDF, IGES, and STEP

- Part development support provision is offered on-site; telephone assistance is available for a fee until the part development phase has been completed

Tools designed by Ranly can be built at the manufacture of your choice or Ranly Design can provide/recommend a supplier.